What is important- Radar or Slope Management Plan?

In the last few decades, a good number of deformation monitoring instruments have been introduced for open pit slope, mainly to measure the spatial distribution of slope movement over time which is the main analysis factor for a geotechnical engineer. The range of accuracy varies from a few centimeters to less than a millimeter for those deformation monitoring instruments. Obviously, accuracy plays a major role in deformation analysis but ‘accuracy’ will have no meaning if mine management does not develop a proper strategy for an early warning system to detect the time of failure (TOF). Pre and post-installation strategies will actually define the strength of a geotechnical cell in a mine. The strategy before procurement of instrument for specific applicability and the strategy after installation of a monitoring instrument to detect slope behavior and the emergency plan in terms of Trigger Action Response Plan (TARP) are the main tools to manage risks of unexpected slope instabilities in open pit mine. This article presents will give us an idea about the importance of slope management plan, monitoring instrument, and monitoring protocol. And also we will know what is most important out of these three things to determine the Time of Failure and to save man-machinery.

Keywords: Ground-Based Radar, Slope Management Plan(SMP), Real-time deformation, Time of Failure (TOF), Inverse velocity, Trigger Action Response Plan (TARP)

- INTRODUCTION

The risk management for personnel, equipment, and production regarding slope instability is one of the most important roles for mining engineers. Both for metal mines and coal mines- the risk mechanisms are the same but the scenarios are different because of the geometry, rock structure, and the differences in ultimate working depth and ultimate pit angle. The interesting fact is that if all these factors remain the same for two different mines then also the amount of deformation before collapsing will vary in a long-range because of the difference in intrinsic properties of different rock types. If intrinsic properties remain the same then also the deformation limit may vary because of the difference in time of exposure and external effects on different slope geometries.

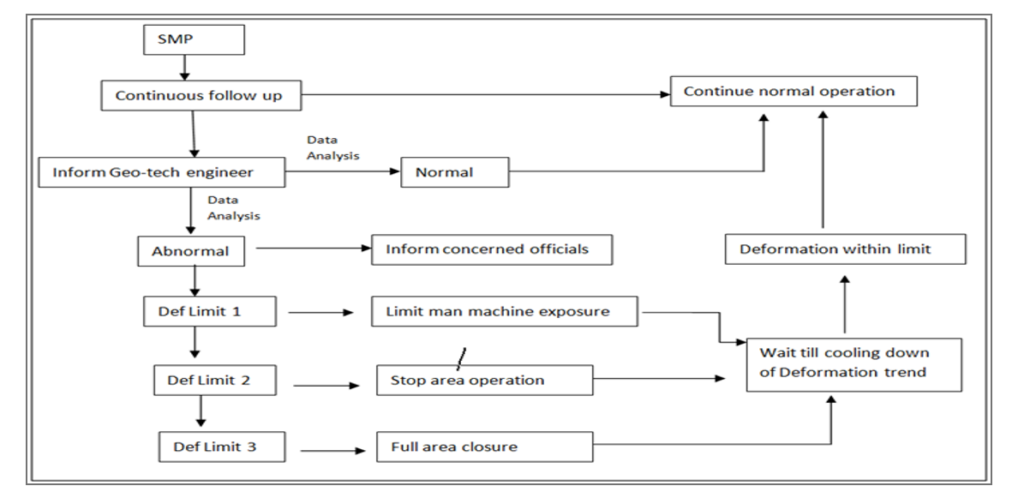

A lot of data collection, data analysis, experience for a particular site, and ultimately the strategy-making can help a geotechnical engineer to develop a protocol for that particular site for the prediction of slope behavior. One side the strategy to know slope behavior and another side Trigger Action Response Plan (TARP) will make a complete package of slope management plan.

The common questions of mine management to establish a methodology should be—

- How much total cumulative deformation is acceptable for a particular slope?

- How much rate of deformation is acceptable and for how much time?

- What should be our geotechnical alarm limit and what should be our critical alarm limit?

- Which instrument should we consider for TARP?

- What type of noise should we filter and what type of trend is acceptable?

- What should be our strategy to stop and resume operation?

What are the factors that we need to consider for developing the protocol for slope monitoring—

- Site applicability of different deformation monitoring instrument

- Man and machinery exposure limit

- Accessibility of the site for installation of monitoring device

- Young modulus of the rock type

- Brittleness/ ductileness of the rock-

- Orientation of joints and other structures

- Geometry of the slopes

- Time of slope exposure

- WRONG CONCEPTS

Before going to the methodology to develop the protocol for early warning system we need to cross the boundaries which can trail us towards confusion. Those boundaries are actually some wrong concepts which are forcing miners not to implement geotechnical instrumentations for slope stability; across the country. The wrong concepts are—

- Accuracy is the ultimate factor regarding selection of monitoring instrument

- Conventional method of monitoring and other monitoring system is not required if we install ground based radar

- Cost of radar is very high

- Mine Management can be in relaxed mood because radar will detect and predict failure

- Always inverse velocity method will be applicable to determine TOF

- Geo-technical slope failure and slope collapse is same

- Radar will always give accurate deformation data

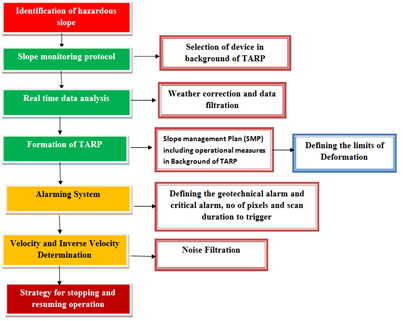

- FLOWCHART TO MANAGE A SLOPE : The methodology for developing protocol of slope monitoring, early warning system and time of failure prediction can be summarized stepwise (Figure 1) as mentioned below—

| Figure 1: Flowchart for strategy and potocol developnent for early warning system |

4.0 What is early warning system and how to link it with TARP?

Early warning system is nothing but an alarming system in emergency situation. Now-a-days almost all hi-tech monitoring instruments are providing the alarming system after crossing the threshold limit decided by geo-tech engineer. All ground based radars have alarming system, all the laser scan based instruments are also proving alarming system, three dimensional based LiDAR, TDR, Micro seismic method and even the robotic total stations are also providing early warning system in alarming method to alert people regarding emergency situation.

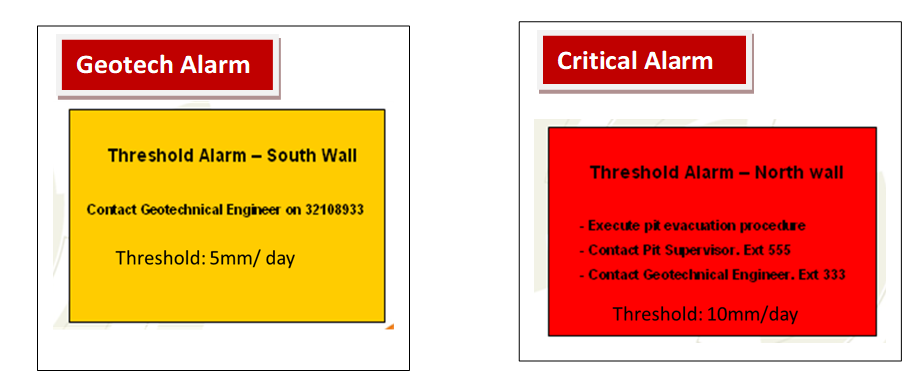

For Trigger Action Response Plan (TARP), different conditions and limits of SSR data has to be defined. Triggering points in terms of rate of deformation and number of scans is to be mentioned in the TARP document.

Different alarm can be fixed as triggering events (Figure 8) in TARP, for different range of deformation (Figure 9). Generally geo-tech engineer should 2 or 3 different alarm according to the seriousness of the rate of deformation amount.

Example of Different alarms of Monitoring instruments

An example of specific TARP for mine premises

From the above-mentioned theories, we can easily conclude that prediction of time of failure and proper TARP implementation is not that much easy process. Obviously suitable instrument i.e. Ground based Radars makes the Geotech engineers’ life very easy in predicting the slope behavior but considering the shape and size of a mine, every time it may not be possible to manage all the slopes of a mine by using a single Radar. This instrument has enormous power and capacity to save man-machinery but without a proper monitoring protocol and proper TARP, it is not possible to save man and machinery by evacuating them from the critical area. And without making a slope management plan, by implementing only the radar technology, we can not manage every slope of our mine. Somewhere we need only conventional monitoring instrument, somewhere we need line of site monitoring instrument, some where we need 3d monitoring instrument. These are completely dependent on the site specific requirement and confidence of site geotechnical engineer. It’s not like that- we have installed radar and it will save our man-machinery. There are more than 5 pillars in the slope management plan, i.e. Numerical simulation, monitoring & data analysis, operational measures, slope stabilization, and trigger Action response plan (TARP) including training etc. In recent trends-in India, people are talking about monitoring pillar only out of those 5 pillars. And Radar is only one part of this 2nd pillar (monitoring) which covers below 30% of the 2nd pillar only. Hence we can understand slope management plan is a huge thing that is much more important than a particular instrument. If slope management plan is robust that it can cover everything which we need.