How a Geotechnical engineer confirms the stability of a slope through Numerical simulation

- Area identification

As per the requirement of the ABP target and approved mine scheme, areas are to be decided by the mine planning engineer where mining excavation will be done in near future. It can be in bench-scale, inter-ramp scale or large scale. That identified area is to be approved by a mine planning engineer.

2. Rock/ rockmass/ properties and collection of other inputs

After identifying the area, all rock properties data from already been tested from the laboratory to be gathered. The field observational data, geometrical data and all geological data i.e compressive strength, tensile strength, shear strength, cohesion, poison’s ratio, young modulus and other rock/ site-specific constants, which are needed for numerical modelling need to be gathered.

3. Structural modelling

All structural data i.e. joint properties, fault/fold/dyke attributes and shear zone related data to be collected as an input for numerical modelling. Hydrogeological data is also to be recorded. RMR, mRMR, RQD, GSI and other geotechnical data are also required for numerical simulation.

4. Pit design/ dump design

Either the mine planning engineer will provide the pit design in Dxf format or the Geotech engineer will design pits in planning software. These pit/dump design geometries will be the main input for the numerical simulation.

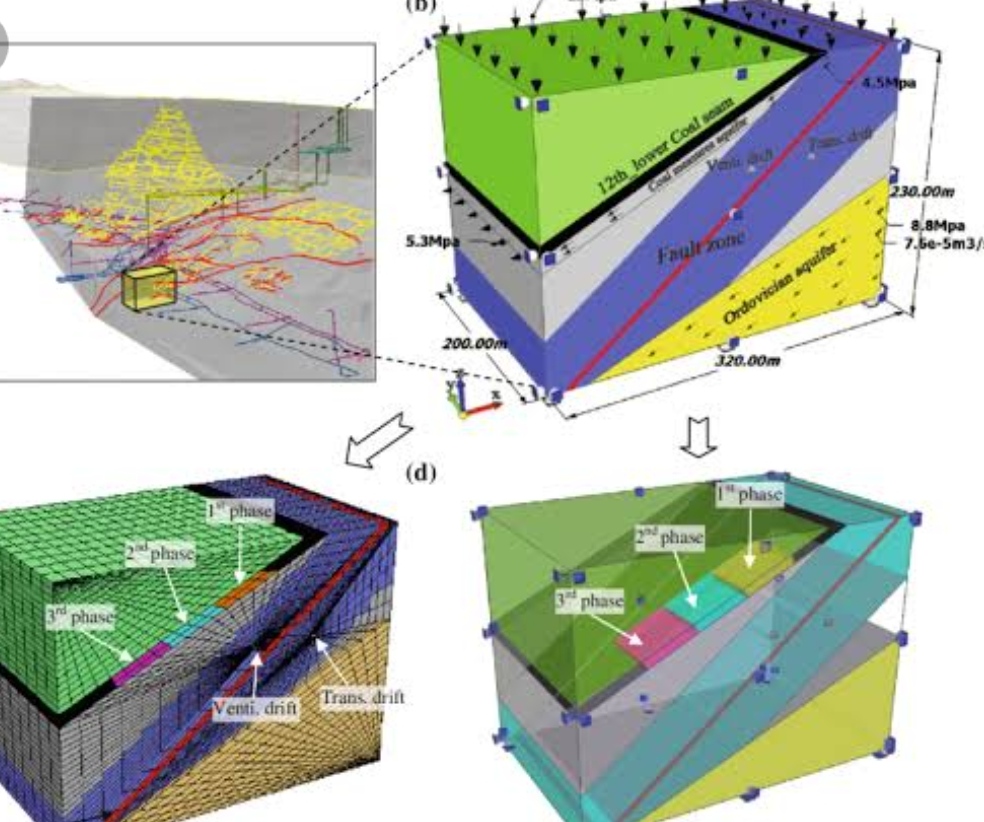

5. Numerical modelling and FOS determination

Considering all the geological, geometrical and other mining parameters, numerical modelling shall be done in a number of iterations to determine the Factor of safety in each concerned section. For numerical modelling, any readily available method (BEM/FEM/DEM) in either 2D or 3D can be used.

6. Analysis of the numerical model result

Geotech engineer will analyze all the results of numerical simulation determined by the modelling software. Those shall be discussed with the mine manager, production engineers and mine management for their acceptance. Displacement analysis, damage analysis and stress analysis shall also be analyzed by geotechnical engineers ad planning engineers.

7. Aligning the design with govt/ statutory guidelines

Not only the acceptance of mine management but also the designs will be aligned with all the statutory guidelines (i.e DGMS, IBM, MoEF, PCB etc)

8. Re-interpretation and redesign of pit and dump

If the numerical simulation result is OK and accepted by the mine management then those designs shall be released for fiel implementation but those are not OK, then again reiteration shall be done considering different input parameters.

9. Finalization of pit design/ dump design

If all the output results seem OK, then those designs shall be released to the production dept for field implementation.

RESOURCES REQUIREMENT:

- A trained Geotechnical engineer (Mining engg/ geologist or Civil engg)

- Trained mining engineer in mine planning software

- High configuration desktop/laptop system (at least 32GB RAM)

- Mine planning software (SURPAC/ Data mine/ Vulcan or similar software)

- Numerical modelling software (FLAC/MAP/Phase/UDEC/3DEC/Plaxis/Galena/Slide or similar software)

![]()